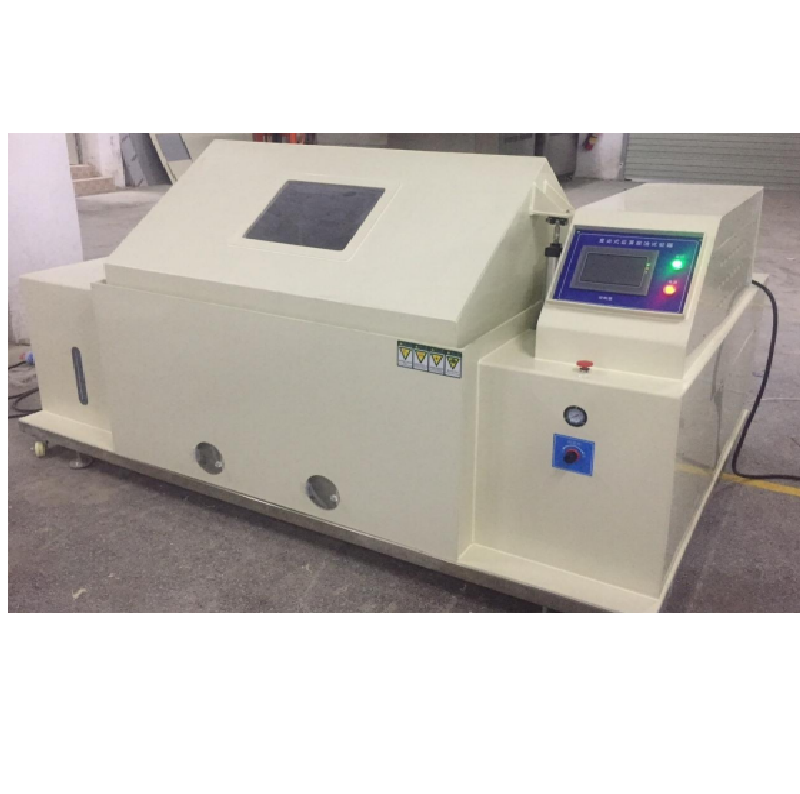

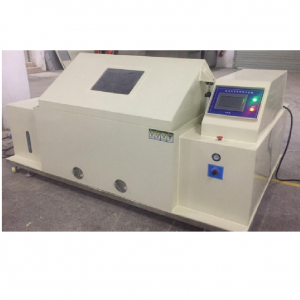

Tủ khí hậu có phun muối

Model: YWX-960FH

Standards

– GB/T5170.8, GB/T10587, GJB150.11, GB/T10125, GB/T2423.17

– ASTM G85 Automotive industry standard

– Working Room Size: 1200×800×1000(W×D×H)mm

– External Size: 2500×1200×1900(W×D×H)mm

– Net Weight: About 800kg

– Temperature Range: -40 ~ +90℃

– Temperature Fluctuation: ±0.5℃

– Humidity Range: 20% ~ 98%RH

– Humidity Fluctuation: ±2.0%RH

– Power Supply: 380V 20KW 50HZ MAX 30A

– Materials: PVC Acid and alkali resistant material

+ The refill water tank for NaCl adopts hidden water level gauge, which is easy to clean and not easy to break.

+ SUS#304 stainless steel high-pressure barrel is the best insulation effect for saturated air barrel.

* Salt spray test

– wettest Saline spray Laboratory: NSS, CASS

– Room Temperature:10℃~50℃

– Saturated air barrel temperature: 47℃ ±1℃

* Wet Test

– Room Temperature: 40℃ ±2℃

– Room Humidity: 93% ~ 100%RH

– Saturated air barrel temperature: 47℃ ±1℃

– Dry Test Room Temperature:15℃~50℃ ±1℃

– Humidity: ≥30%RH

Air Supply System

– Air pressure is 1kg/cm2 divided into two stages of adjustment, the first is the imported pressure regulating filter with filter water function,

– Approximately adjusted to 2-2.5kg/ cm2, the second for imported precision pressure regulating valve, adjusted to pressure gauge 1kg/ cm2 pressure gauge.

Spray Way

– Adopt Benoit principle to suck brine and then atomize, atomization degree is uniform, no blocking crystallization phenomenon, to ensure the standard of continuous testing.

– Nozzle: made of special glass nozzle, can adjust the size of spray volume and spray Angle.

– Spray volume: adjustable 1.5 ± 0.5ml 80cm2/Hr (16-hour average volume).

– 40L large brine tank can spray continuously for 48HR. Heat System

– External hot air heating method, fast heating speed to reduce standby time, low component damage rate.

– Using S.S.R control heating power, accurate temperature, less power consumption. (Titanium alloy corrosion prevention tube adopted by electric heat pipe)

Electric Control System

– The main controller adopts 7-inch LCD man-machine interface, and the main screen can plan the test program.

– Fixed conditions can be set time 0-999 H 59 MIN.

– Program mode can be set at the same time salt spray, wet test

– With power off memory device, can continue to perform the rest of the program when the power back.

– Temperature and temperature can be used for rate control, and has the function of self-correcting temperature and humidity reference point.

– Temperature and humidity sensor using DIN PT-100Ω (platinum induction). Water supply and drainage system

– When the water level is too low, it will be automatically replenished and can be manually replenished.

– Drainage adopts acid and alkali resistant and corrosion resistant pump to increase service life and reduce waiting time for drainage.

– All pipe fittings are imported acid and alkali resistant corrosion resistant components, long life. Humidity System

– Adopt electronic bit P.I.D micromotion humidifier system.

– Double protection device for overheating and overflow.

– The humidification and dehumidification systems are completely independent.

– Water level control of high mining molecular floating ball water valve.

– Fully automatic humidifying water supplement device. (The machine shall be connected to water source) Dehumidify System

– Using refrigeration evaporator condensation dehumidification method, humidity stability.

– The bubble accelerates the humidifier and the humidity stabilizes at a fast rate

– Adopt high speed return air exhaust system. Protection Devices

– With leakage power off type fusible protection switch.

– Low water level protection switch.

– Low salt liquid protection switch

– Double over-temperature protection device, prevent mechanical action or electronic action out of control

Liên hệ:

Hotline : 097.252.0991 – 097.844.2238

Email: info@instec.vn , trieu.vu@instec.vn ,tien.vd@instec.vn

Đánh giá

Chưa có đánh giá nào.